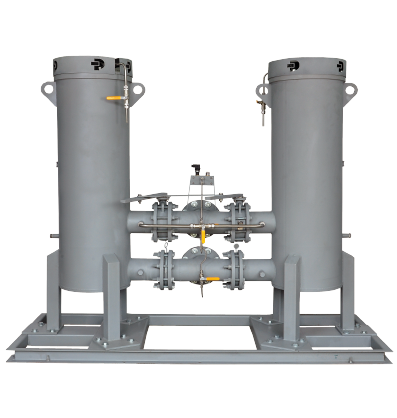

Duplex Filter

High Flow Single & Duplex Series

Heavy Duty Reliability

New High Flow Single and Duplex Filters ensure reliability in industrial, marine, and power generation applications up to DN350 and ow rates up to 11200 l / min. One filter element size allows standardisation in multi – element housings. Equalising valve eases changeover of ow direction in filter housings. Patented angular sealing arrangement aids installation of elements.

Application

- Steel industry, paper mills, marine applications and power generation

- Lubricating systems

- Fuel filtration

- Coolant filtration

Assembly

In-line Filter as a Single Filter or a Duplex Filter. Single Filters are available with connections on the same side or on opposite sides. Duplex Filters are available either with a L – bore ball valve in upstream and downstream lines or with two butterfly valves in the upstream line and two flap-type check valves in the downstream line.

Maximum operating pressure

10 bar

Nominal ow rate (30 cSt)

Up to 11200 l/min (672 m3/h).

Connections

Flanges: DN50 – DN350 / PN10.

ANSI flanges upon request.

Seal Material

Nitrile

Other seal materials upon request.

Operating Temperature

0°C…+100°C

Housing Material

Steel

Stainless steel upon request.

Weight

Single Filters: Approximately 5 – 550 Kgs.

Duplex Filters: Approximately 100 – 1700 Kgs.

Bypass Valve

Opening pressure 3,5 bar or without a bypass.

Filter Elements

Environmentally friendly Ecoglass III.

Resin impregnated heavy duty cellulose paper 15 μm nominal.

Cleanable wire mesh.

Differential Pressure Indicators

Filter can be equipped with a visual, electrical or electronic indicator with setting 2,5 bar.

Fluid Compatibility

Suitable for use with regular hydraulic and lubrication oils. For suitability with other fluids consult with us.

Descriptions

Heavy Duty Reliability

New High Flow Single and Duplex Filters ensure reliability in industrial, marine, and power generation applications up to DN350 and ow rates up to 11200 l/min. One filter element size allows standardisation in multi-element housings. Equalising valve eases changeover of ow direction in filter housings. Patented angular sealing arrangement aids installation of elements.Application

- Steel industry, paper mills, marine applications and power generation

- Lubricating systems

- Fuel filtration

- Coolant filtration

Assembly

In-line lter as a single lter or a duplex lter. Single Filters are available with connections on the same side or on opposite sides. Duplex Filters are available either with a L-bore ball valve in upstream and downstream lines or with two butterfly valves in the upstream line and two flap-type check valves in the downstream line.Specifications

Maximum operating pressure

10 bar

Nominal ow rate (30 cSt)

Up to 11200 l/min (672 m3/h).

Connections

Flanges: DN50 – DN350 / PN10.

ANSI flanges upon request.

Seal Material

Nitrile

Other seal materials upon request.

Operating Temperature

0°C…+100°C

Housing Material

Steel Stainless steel upon request.

Weight

Single Filters: Approximately 5 – 550 Kgs.

Duplex Filters: Approximately 100 – 1700 Kgs.

Bypass Valve

Opening pressure 3,5 bar or without a bypass.

Filter Elements

Environmentally friendly Ecoglass III.

Resin impregnated heavy duty cellulose paper 15 μm nominal.

Cleanable wire mesh.

Differential Pressure Indicators

Filter can be equipped with a visual, electrical or electronic indicator with setting 2,5 bar.

Fluid Compatibility

Suitable for use with regular hydraulic and lubrication oils. For suitability with other fluids consult with us.